Shop Premium Used Screw Compressors | Industrial Refrigeration Solutions

- Specifications

- FAQs

- ←

- →

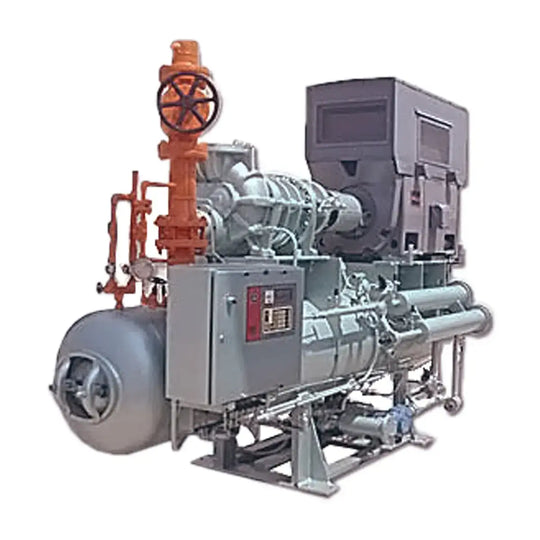

An industrial screw compressor is a key component in refrigeration systems and is widely used in various industries. It's specially designed to compress gases, effectively providing efficient cooling for refrigeration applications. Commonly used refrigerants like ammonia and freon enter the rotary compressor at low pressure and temperature. The compressor then acts as a mechanism to compress and push the refrigerant to a higher pressure and temperature level.

The compressed refrigerant is then able to flow seamlessly through the condenser and evaporators within the refrigeration system. In the condenser, the high-pressure refrigerant releases heat energy to the surrounding environment, causing it to condense from a vapor state to a liquid state. This condensation process allows the system to effectively get rid of heat and reduce the temperature of the refrigerant.

Once the refrigerant has gone through the condenser, it enters the evaporator, where it undergoes a phase change from liquid to vapor. As it absorbs heat from the surrounding environment, the temperature of the refrigerant rises. This heat absorption process is what enables the refrigeration system to cool down the desired space or area.

The screw compressor plays a necessary role in raising the pressure and temperature of refrigerants, allowing for efficient heat transfer and effective cooling within the refrigeration system. By enabling the smooth flow of the compressed refrigerant through the condenser and evaporator, the compressor helps maintain the desired temperature and facilitate the refrigeration process.

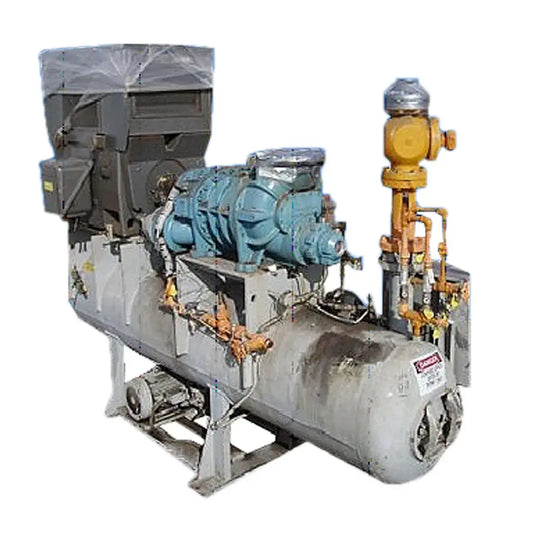

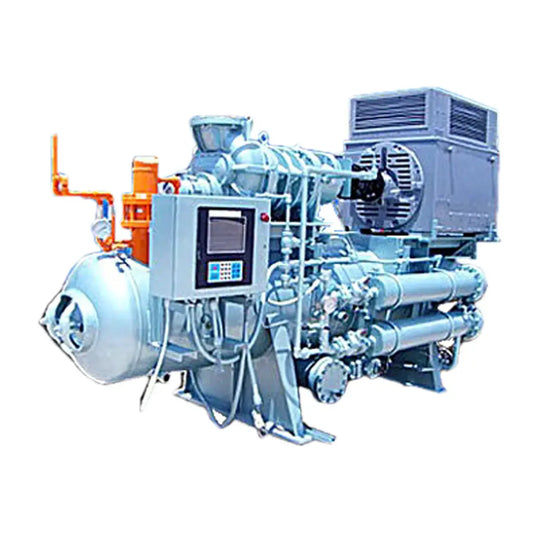

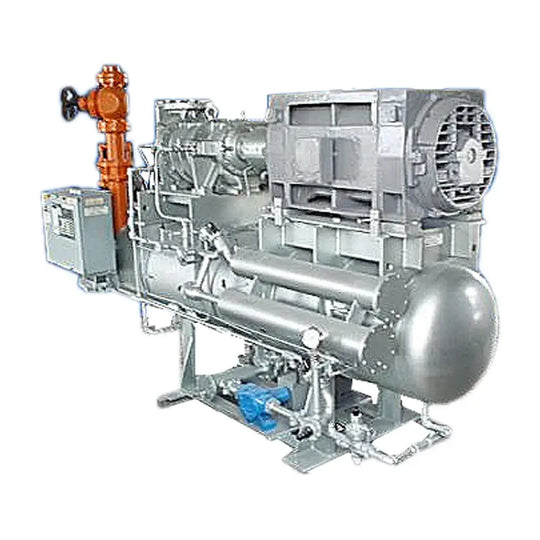

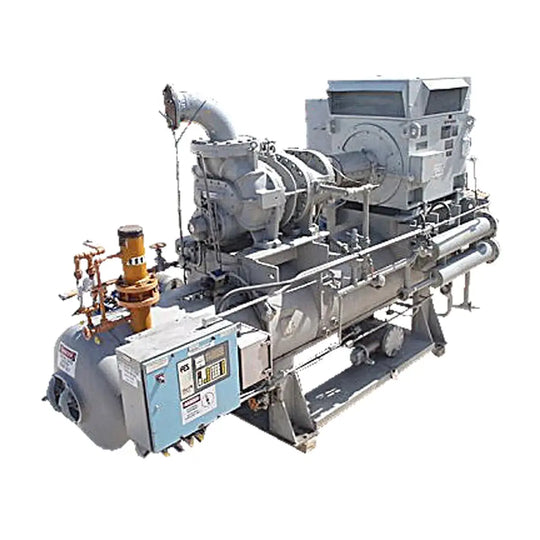

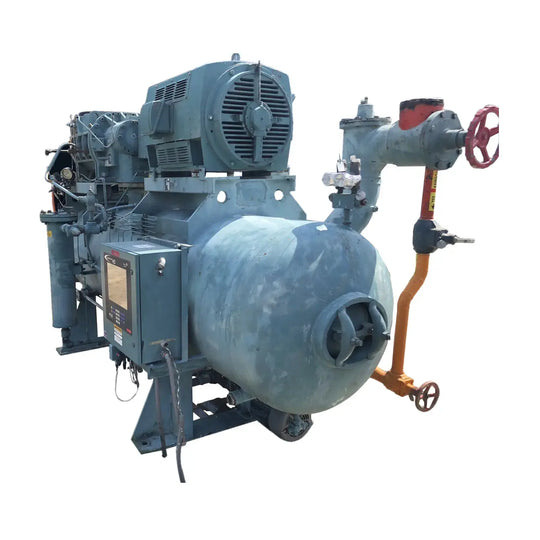

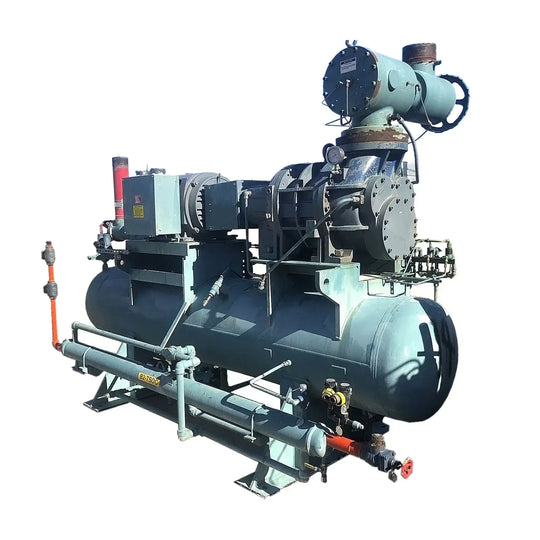

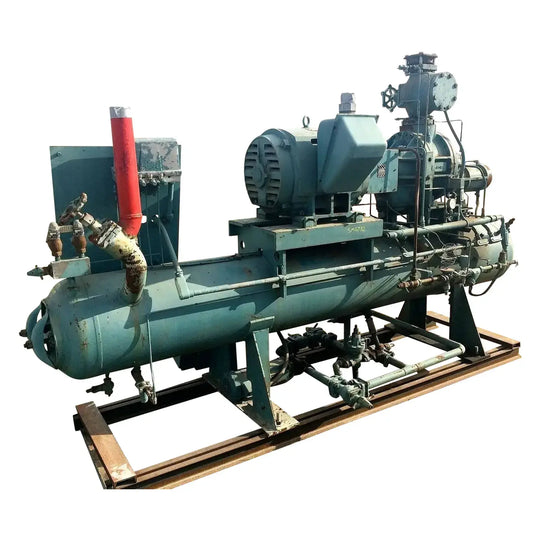

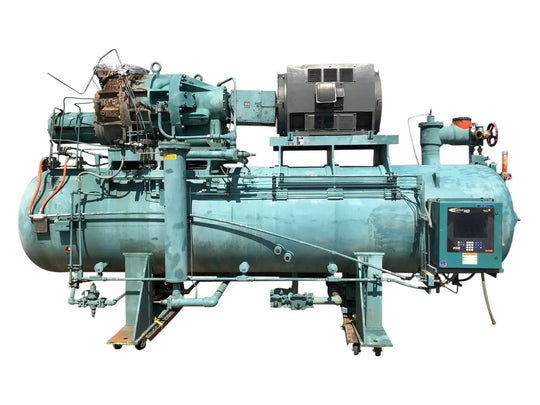

If you are in the market for industrial compressors, Genemco is the one-stop destination for rotary compressor packages. We take pride in offering a wide range of compressors for sale to provide you with peace of mind when making your purchase. With our diverse selection, you can find the perfect match for your industrial requirements.

Some of the premium compressor manufacturers we carry include Frick, GEA, FES, Dunham-Bush, Howden, Kobe, Kobelco, and Mycom. Each of these brands is known for its exceptional quality, reliability, and performance. By offering equipment from reputable manufacturers, we ensure that our customers have access to the best compressors in the industry. Our range includes compressors of different capacities and specifications to meet the unique demands of various industrial applications. With the support and expertise of our dedicated team, we can help you choose the most suitable option for your specific needs. We also offer bare screw compressors and incomplete screw compressor packages.

When it comes to refrigeration systems, there are several other components that are essential for an efficient and functional operation. These components include evaporative condensers, compressors, and ammonia vessels.

Condensers help to remove heat from the refrigerant by using a combination of air and water. As the refrigerant passes through the condenser, it is exposed to cool air created by the evaporation of water. This cools down the refrigerant, allowing it to be circulated back into the system for further cooling. Evaporative condensers are particularly effective, as they can maintain optimal operating temperatures regardless of external environmental conditions.

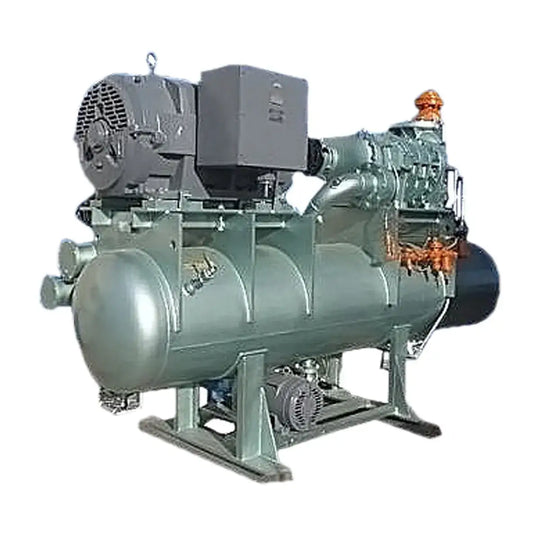

Another essential component in a refrigeration system is the compressor. These compressors are responsible for compressing the refrigerant and increasing its pressure, enabling it to absorb heat efficiently. Screw compressors, in particular, are popular in refrigeration systems due to their high efficiency and reliability. These compressors use two interlocking screws to compress the refrigerant, creating a tight seal and minimizing any leakage. This design allows for continuous operation without any pulsations or vibrations, resulting in smooth and consistent refrigerant circulation.

Ammonia vessels are crucial in industrial refrigeration systems that use ammonia as a refrigerant. Ammonia vessels store large quantities of ammonia, which is highly effective at absorbing and releasing heat. These vessels ensure a steady supply of ammonia to the system, enabling efficient cooling and maintaining optimal temperatures.

But for these components to work together to keep a space cool, evaporators are also essential. Evaporators are the components of the system that the cold refrigerant passes through to make a space cold.

Screw compressors are preferred in refrigeration due to their exceptional efficiency and reliability. They possess the capability to handle a wide range of operating conditions, making them a preferable choice for various applications, including commercial refrigeration, industrial cooling processes, and air conditioning systems. These compressors excel in large-scale refrigeration systems where high cooling capacities are essential to provide adequate cooling for expansive spaces or industrial processes.

One of the key advantages of rotary compressors is their high energy efficiency. Compared to conventional compressors, they require less power to operate and generate minimal heat during compression. This results in significant energy savings and lower operating costs. Their efficiency is further enhanced by their ability to handle different operating conditions, ensuring consistent performance even in varying loads and ambient conditions.

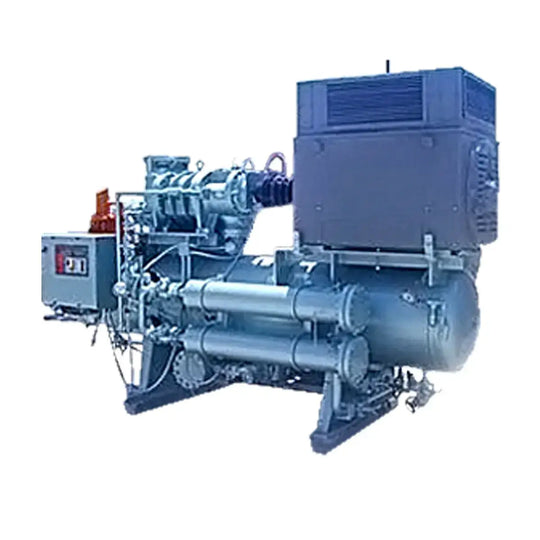

Screw compressors are also known for their low oil consumption and oil carryover rate. They consume less oil compared to other oil-flooded compressor models, reducing the need for frequent oil changes and maintenance. This not only saves costs but also enhances the reliability and longevity of the compressor, leading to fewer breakdowns and repairs. We also offer single-stage, two-stage, and high-stage compressors.

The primary distinction between a rotary compressor and a piston compressor lies in the compression method employed within each unit. Screw-type compressors utilize twin interlocking helical screws to accomplish compression. This mechanism operates by drawing in air through the screw rotors, which subsequently compresses the air as it moves along the rotating screws. The compression process within a screw compressor is continuous, providing a steady flow of compressed air.

On the other hand, piston compressors use pistons that are powered by an oscillating crankshaft. As the crankshaft spins, the pistons move up and down within the cylinder, thereby compressing the air in the process. Unlike screw compressors, the compression in piston compressors occurs in a pulsating manner. This means that the air is compressed in bursts, resulting in intermittent flow of compressed air.

Furthermore, both screw and piston compressors are available in oil-lubricated and oil-free variants. Oil-lubricated compressors utilize oil for lubrication purposes, which helps reduce friction and extend the lifespan of the compressor. In contrast, oil-free compressors do not require any lubrication as they are designed to operate without the need for oil. This makes them suitable for applications that demand clean and contaminant-free compressed air, such as in the food and pharmaceutical industries.